Phone: 1-800-506-3924 (toll free US only)

Phone: 1-215-526-2300 (worldwide)

Email: info@newageindustries.com

![]()

![]()

![]()

Crush Resistant Brewery Hose

Monofilament Reinforced, Butyl Hose; rebounds to its original shape after impact

![]()

Notes

| Construction | |

| Liner: | White FDA Butyl rubber |

| Reinforcement: | Multiple plies of polyester with monofilament polymer helix |

| Cover: | Brick Red EPDM rubber |

Fitting Styles Available

-

Tri-Clamp®

-

Collars

-

Hinge Clamps

All recommended fittings, collars, hinge clamps and accessories are made from 300 series stainless steel.

Physical Properties**

| Minimum Operating Temp., °F |

-40 |

| Maximum Operating Temp., °F |

240 |

| Working Pressure at 70 °F (21.1°C) |

250psi |

**Values listed are typical for the material used in manufacture, except where noted, and are meant only as a guide to aid in design. Field testing should be per- formed to find the actual values for your application.

Introducing BrewSavor® by NewAge Industries – manufacturing tubing and hose products for both low and high temperature applications in the brewing process. There are many BrewSavor products to meet your Craft Brewery needs.

- Crush resistant; rebounds to its original shape after impact

- Ultra smooth, white, chlorobutyl rubber liner offers high purity; minimizes bacterial

entrapment and flavor contamination - Microbe-resistant liner is built on stainless steel mandrels for cleanliness and will not impart taste or odor

- General temperature range: -40°F to 240°F

- Multi-layered and reinforced with a monofilament polymer helix Made in U.S.A.

- Hose meets FDA, USDA and Canadian Food Inspection Agency (file: N267) standards

- Butyl compound used conforms to 3-A Sanitary Standards for #18-03

- Free of PVC, phthalates and animal-derived ingredients

- REACH compliant

- 316 Stainless Steel Tri-Clamp® fittings engineered specifically for butyl hose

SPECIFICATIONS |

|||||

| PART NUMBER |

I.D. (IN.) |

O.D. (IN.) |

VACUUM RATING (IN./Hg.) |

BEND RADIUS (IN.) |

LBS. PER FT. |

| 452 1000 | 1 | 1.64 | 29.9 | 3.5 | 0.44 |

| 452 1500 | 1.5 | 2.14 | 29.9 | 4.5 | 0.63 |

| 452 2000 | 2 | 2.77 | 29.9 | 7 | 1.21 |

NOTE: Available in standard lengths of 10, 20, 25 and 50 feet. The data listed throughout this web site is meant only as a guide to aid in design, and is believed to be reliable; however, nothing stated shall constitute a guarantee or warranty for any application. Product field-testing should be performed to find the actual values for a specific application. Specifications are subject to change without notice. |

|||||

Craft Beer Hose Assemblies

Food and Beverage Grade Brew Hose and Sanitary Fittings

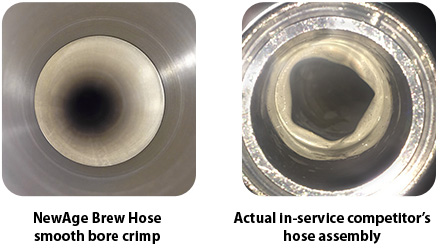

You invest a lot of time, energy and money in your brew. Why take a chance of ruining it with bacterial entrapment and flavor contamination? With our extensive knowledge learned from the pharmaceutical industry, our hose assembly crimp technology offers smooth hose-to-fitting transitions for unrestricted flow.

Which hose assembly would you rather run your beer through?