Phone: 1-800-506-3924 (toll free US only)

Phone: 1-215-526-2300 (worldwide)

Email: info@newageindustries.com

![]()

![]()

![]()

Kink Resistant Brewery Hose

Wire Reinforced, Butyl Hose for Suction & Discharge Applications

![]()

Notes

| Construction | |

| Liner: | White FDA Butyl rubber |

| Reinforcement: | Multiple plies of polyester with helix wire |

| Wire: | Steel helix |

| Cover: | Green EPDM rubber |

Fitting Styles Available

-

Tri-Clamp®

-

Collars

-

Hinge Clamps

All recommended fittings, collars, hinge clamps and accessories are made from 300 series stainless steel.

Physical Properties**

| Minimum Operating Temp., °F |

-40 |

| Maximum Operating Temp., °F |

240 |

| Working Pressure at 70 °F (21.1°C) |

150psi |

**Values listed are typical for the material used in manufacture, except where noted, and are meant only as a guide to aid in design. Field testing should be per- formed to find the actual values for your application.

Introducing BrewSavor® by NewAge Industries – manufacturing tubing and hose products for both low and high temperature applications in the brewing process. There are many BrewSavor products to meet your Craft Brewery needs.

- Kink resistant; tighter bend radius

- Ultra smooth, white, chlorobutyl rubber liner offers high purity; minimizes bacterial

entrapment and flavor contamination - Microbe-resistant liner is built on stainless steel mandrels for cleanliness and will not impart taste or odor

- General temperature range: -40°F to 240°F

- Multi-layered and reinforced with a stainless steel helix wire

- Hose meets FDA, USDA and Canadian Food Inspection Agency (file: N267) standards

- Butyl compound used conforms to 3-A Sanitary Standards for #18-03

- Free of PVC, phthalates and animal-derived ingredients

- REACH compliant

- 316 Stainless Steel Tri-Clamp® fittings engineered specifically for butyl hose

SPECIFICATIONS |

|||||||

| PART NUMBER |

I.D. (IN.) |

O.D. (IN.) |

STANDARD LENGTHS (FT.) |

BEND RADIUS (IN.) |

LBS. PER FT. |

WORKING PRESSURE AT 70°F (PSI) |

VACUUM RATING (IN./Hg.) |

| 451 1000 | 1 | 1.54 | 10, 20 | 5 | 0.50 | 150 | 29.9 |

| 451 1500 | 1.5 | 2.05 | 10, 20 | 6 | 0.71 | 150 | 29.9 |

| 451 2000 | 2 | 2.55 | 10, 20 | 7 | 0.95 | 150 | 29.9 |

The data listed throughout this web site is meant only as a guide to aid in design, and is believed to be reliable; however, nothing stated shall constitute a guarantee or warranty for any application. Product field-testing should be performed to find the actual values for a specific application. Specifications are subject to change without notice. |

|||||||

Craft Beer Hose Assemblies

Food and Beverage Grade Brew Hose and Sanitary Fittings

You invest a lot of time, energy and money in your brew. Why take a chance of ruining it with bacterial entrapment and flavor contamination? Let the professionals at NewAge put together your hose assemblies for you.

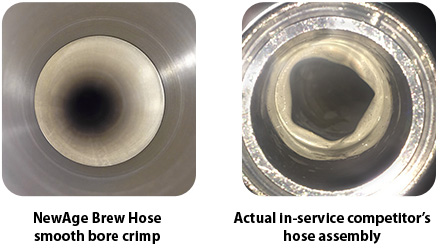

Which hose assembly would you rather run your beer through?

MORE INFORMATION HERE